Sustainable alternative to activated carbon filters.

Learn more

Reduce your energy and maintenance costs,

your carbon footprint, and your waste,

by reducing weights and embracing innovation.

Innovation

A true low-carbon alternative to activated carbon filters, Purenat technology is the first filter that sustainably eliminates VOCs and microorganisms without clogging. Pressure drops are significantly reduced, thus minimizing energy consumption. Its lifespan is extended, reducing waste production and maintenance costs, while providing a competitive advantage that addresses both environmental and economic challenges.

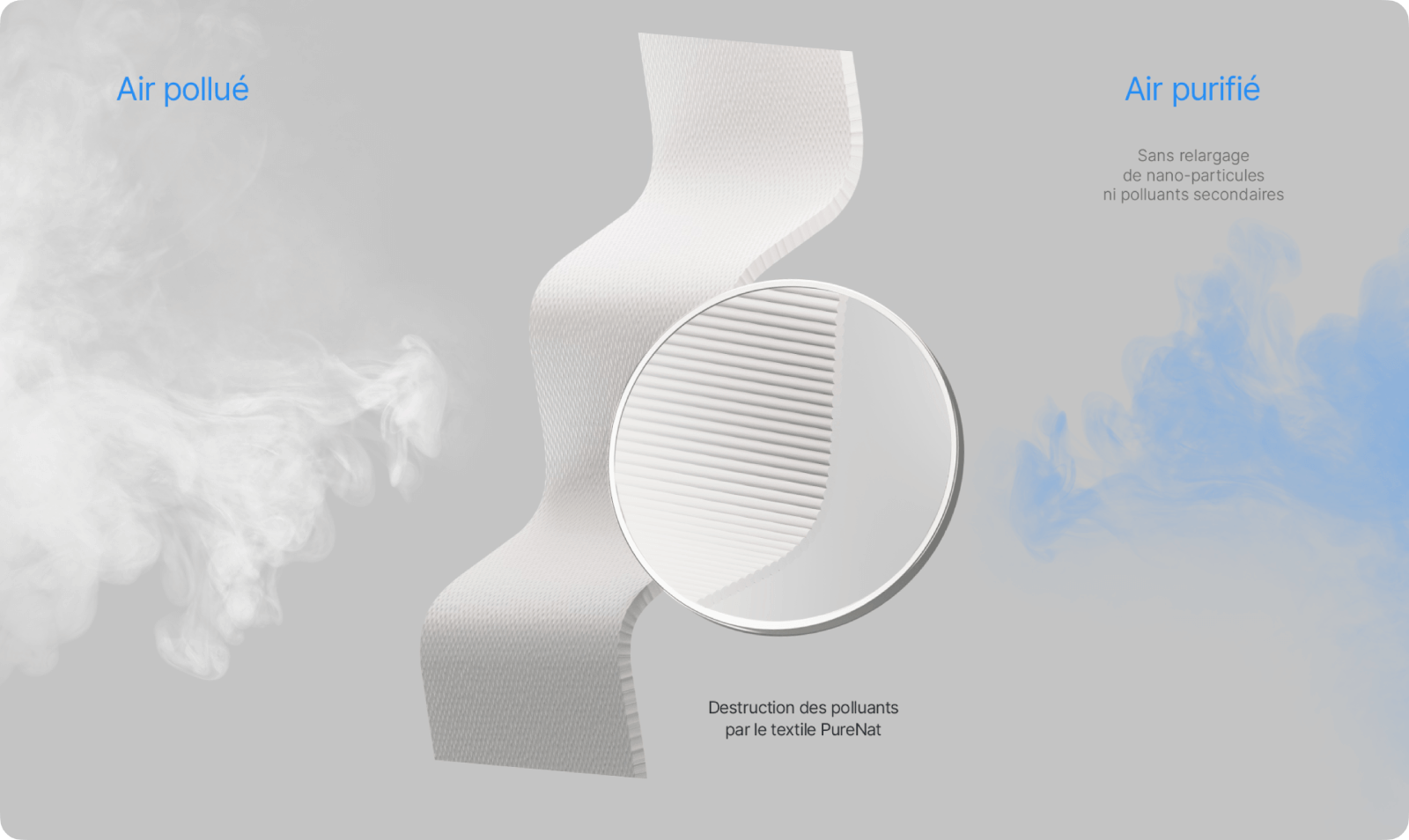

The innovative Purenat material meets the unmet needs of customers by improving air pollution removal efficiency, without releasing secondary pollutants, and offering the possibility to optimize product design to reduce weight and costs. Purenat is the only solution that addresses these three areas of improvement.

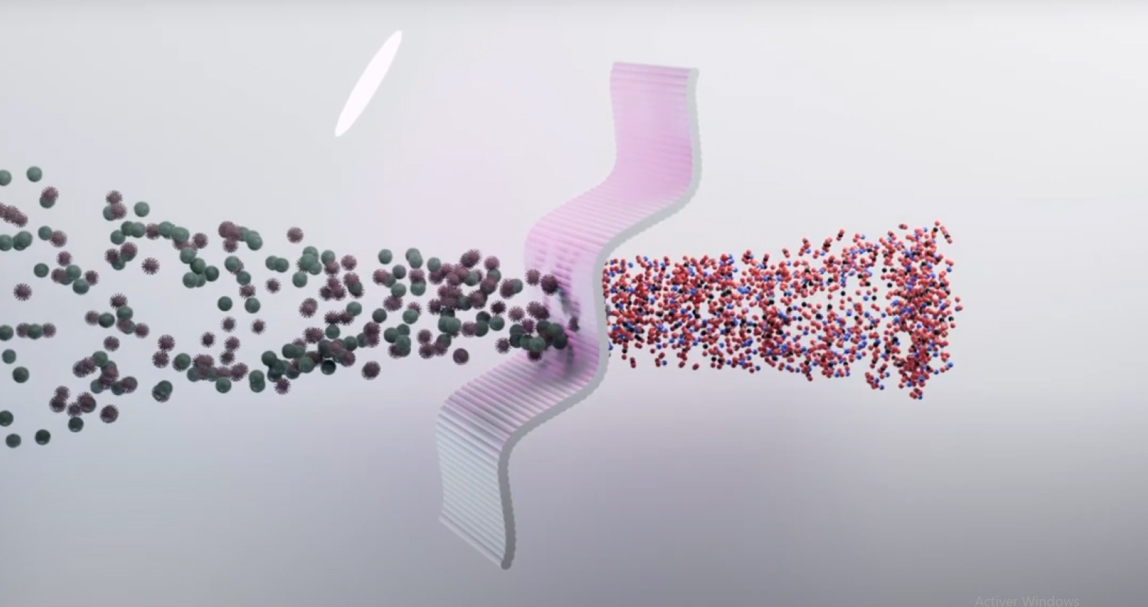

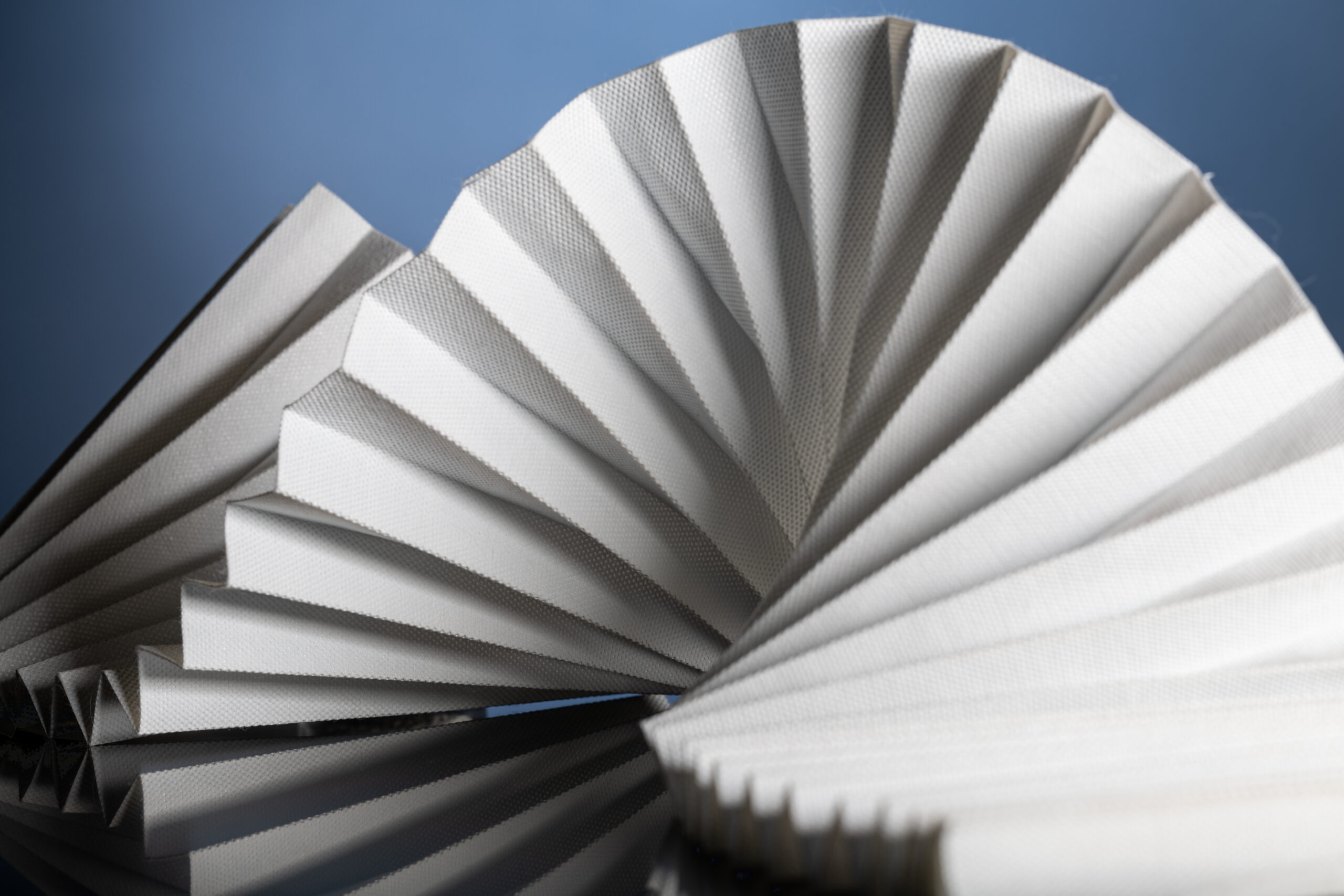

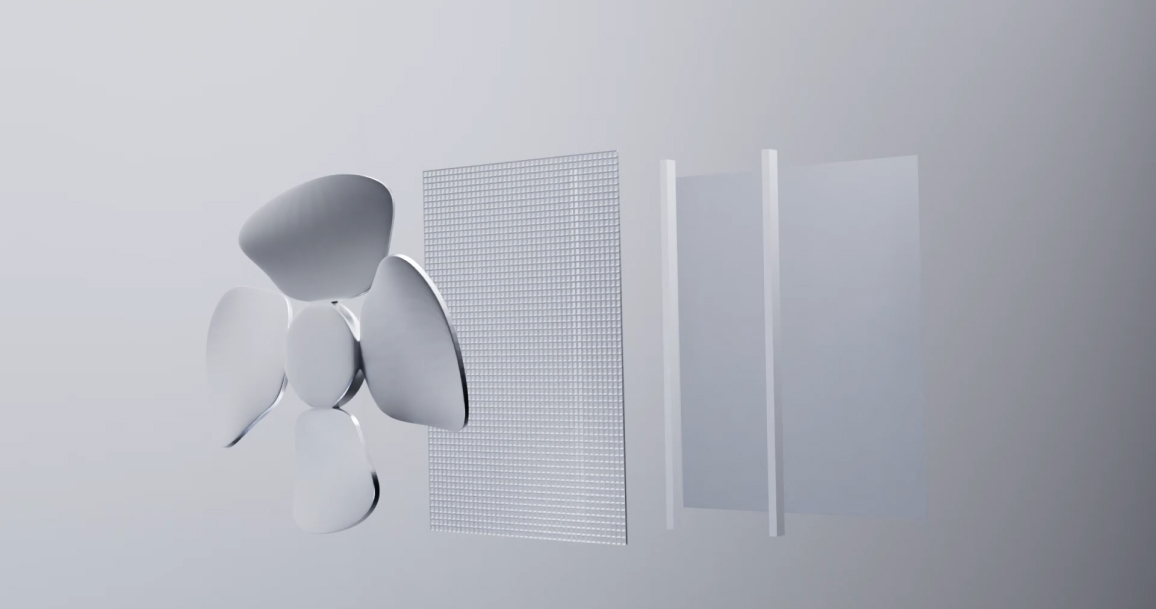

Disruptive innovation: The innovative material developed by Natacha Kinadjian Caplat takes the form of a thread, which is then transformed into fabric through the nonwoven process. The composition of this thread contains an active decontaminating agent (photocatalytic agent) that destroys organic pollutants. This is the first time that a thread, and then a filter, is made of such an active agent rather than just being coated with it. This major technological breakthrough addresses the current flaws in photocatalysis: no loss of efficiency, no release of dangerous nanoparticles, and no generation of harmful by-products. All this, with the added benefit of a flexible and lightweight material for easy integration into air treatment devices.

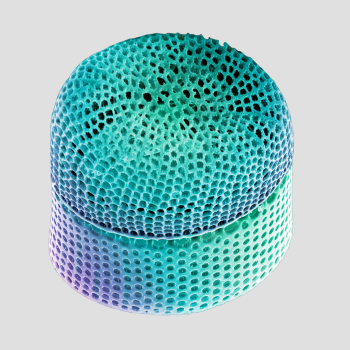

The Purenat thread, which forms the basis of the active filtration media, was developed by drawing inspiration from what naturally exists in the living world. Its three-dimensional structure mimics the alveoli of marine algae, specifically diatoms. A major advantage that provides a perfect balance, never achieved before, maximizing the exchanges between air and the active purifying material for enhanced efficiency.

Our significant technological advancements have led to the granting of a patent. This patent is a testament to our unique expertise in the field of materials and Indoor Air Quality (IAQ). It confirms the value of our air purification technology. It strengthens our position by allowing us to offer exclusive and differentiating solutions to our customers. It reflects our ongoing commitment to research, innovation, and the creation of high-value products.

Optimization of photocatalysis

The core technology, reinvented by Purenat, is photocatalysis. It transforms organic pollutants into minute quantities of carbon dioxide (CO2) and water vapor. The effectiveness of this process in eliminating pollutants has been proven by numerous publications and is widely scientifically recognized. Purenat revolutionizes photocatalysis with an active textile that maintains its efficiency over time and generates no harmful by-products or dangerous release.

Natacha Kinadjian Caplat

Purenat’s Founder

A Doctor in Materials Physico-Chemistry, she is a specialist in Indoor Air Quality (IAQ) with over 12 years of experience. Her passion for IAQ began during her PhD in 2010, where she developed materials to purify air. It was during this time that she became aware of the crucial importance of IAQ as a public health issue.

Solution

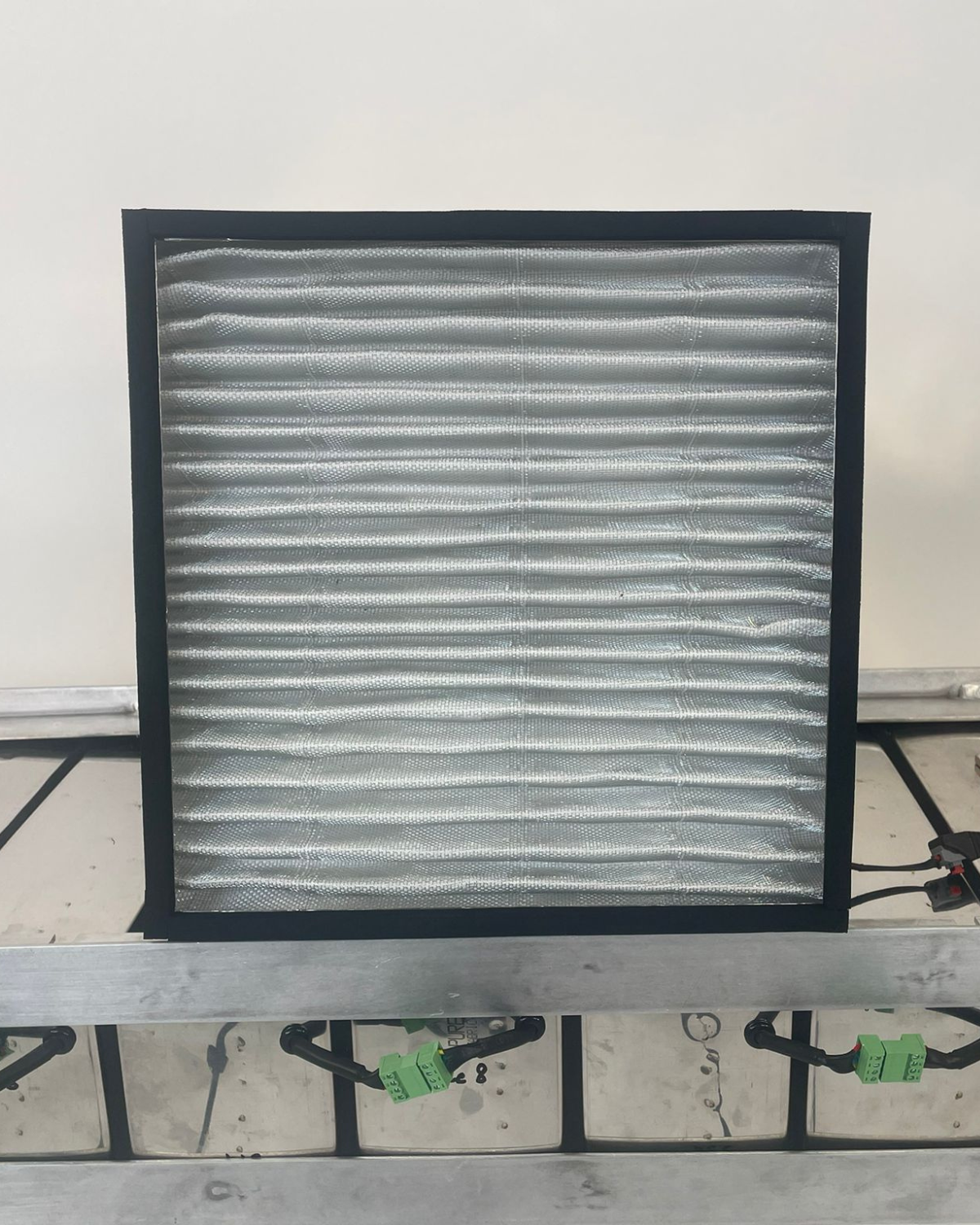

We carry out pilot projects to validate technical choices, measure the savings achieved, and evaluate performance under real-world conditions to meet your challenges and strategic objectives:

• Comply with increasingly strict regulations, particularly in Europe

• Avoid significant fines for non-compliance

• Obtain building permits

• Ensure the sustainability of sites

• Minimize the amount of waste generated

• Ensure the well-being of employees and the surrounding community

• Decarbonization: Scope 3

• Operating costs

• Maintenance expenses

• Waste management

• Energy consumption

• Analysis of constraints

• Definition of the specifications

• Reduction targets

• Design

• Conception

• Manufacturing of a purification unit tailored to your project

• On-site installation in industrial settings

• Real-time monitoring

Detailed report on performance results

• Reduction curves

• Investment and operating costs

• Recommendations for industrial-scale sizing

Accreditations and certifications

Applications

• Reduce pollutant emissions (VOCs, solvents, corrosive vapors, …)

• Ensure regulatory compliance

• Protect the health of operators (OELs)

• Optimize operating costs (CAPEX)

• Reduce environmental impact

• Limit secondary waste

• Ensure product safety by avoiding contamination

• Reduce health risks for workers

• Comply with regulatory standards

• Optimize storage conditions

• Limit environmental impact

• Maintain a healthy working environment

• Reduce secondary waste

• Reduce pollutant emissions: VOCs, toxic gases, odors

• Ensure regulatory compliance

• Ensure the well-being and comfort of the neighborhood and teams

• Control odors

• Reduce operating costs (CAPEX)

• Minimize environmental impact

• Reduce secondary waste

• Address sovereignty challenges

• Space-saving, lightweight, and effective pollutant neutralization

• Multiple levels: in submarines, vehicles, and infrastructures

Partnership : Purenat x Clauger

In 2024, Purenat signed its first commercial partnership with Clauger, a recognized specialist in industrial refrigeration and air treatment, to deploy pilot projects incorporating its patented air-purifying material. This partnership reflects the confidence of industry players in our innovative and high-performance technology and paves the way for further collaborations to jointly tackle the complex challenges of air decontamination.

À propos

À propos